Controlled Numeric Traceability Sheet for 900907501, 695913431, 616363333, 612261702, 120578225, 3332341502

The Controlled Numeric Traceability Sheet is essential for monitoring items 900907501, 695913431, 616363333, 612261702, 120578225, and 3332341502. It ensures meticulous documentation within the manufacturing process. This tool not only aligns with compliance and quality assurance standards but also aids in identifying potential defects promptly. The management of inventory becomes more streamlined, yet the implications of such traceability extend beyond mere organization. What specific advantages might emerge from its implementation?

Importance of Traceability in Manufacturing

Traceability in manufacturing is crucial not only for ensuring product quality but also for maintaining compliance with industry standards and regulations.

It enhances quality assurance by allowing for the identification of defects, thus facilitating timely corrective actions.

Moreover, effective traceability systems improve production efficiency by streamlining processes, reducing waste, and enabling better resource management, ultimately leading to increased operational effectiveness and customer satisfaction.

Overview of the Controlled Numeric Traceability Sheet

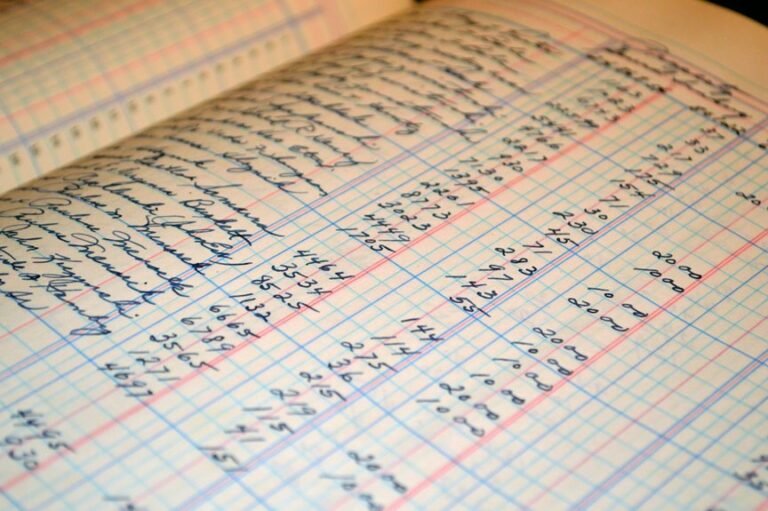

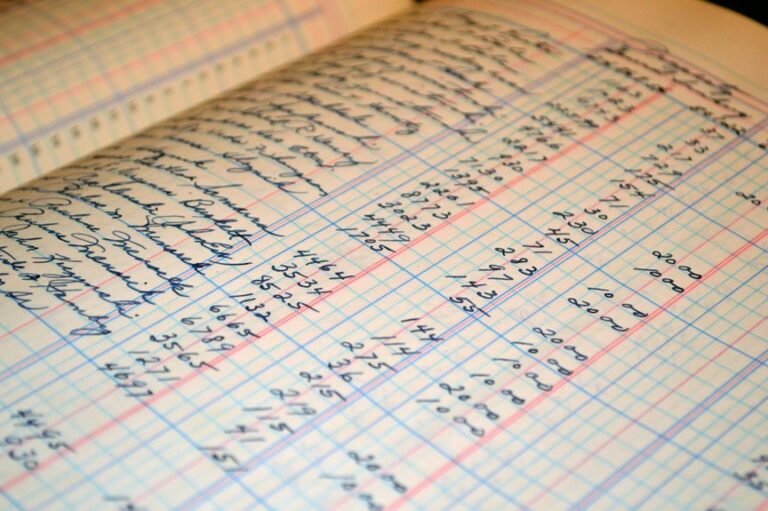

A Controlled Numeric Traceability Sheet serves as a foundational tool in the manufacturing sector, providing a structured approach to tracking and documenting the flow of materials and components throughout the production process.

This system enhances numeric tracking, ensuring data accuracy and facilitating efficient audits.

Implementation Process for Effective Tracking

Implementing an effective tracking system requires a systematic approach to ensure all materials and components are accurately monitored throughout the production cycle.

Key implementation strategies involve integrating advanced tracking technology, such as RFID and barcoding systems, to facilitate real-time data collection.

Consistent training and adherence to standardized procedures further enhance the reliability of the tracking system, promoting transparency and efficiency in operations.

Benefits of Enhanced Accountability in the Supply Chain

While many factors contribute to a robust supply chain, enhanced accountability stands out as a critical element that fosters trust and reliability among stakeholders.

By implementing accountability measures, organizations can improve risk management practices and strengthen inventory control.

This heightened transparency not only mitigates potential disruptions but also empowers stakeholders, ultimately leading to a more efficient and resilient supply chain.

Conclusion

In conclusion, the Controlled Numeric Traceability Sheet serves as a vital tool in the manufacturing process, ensuring that every detail is meticulously recorded and managed. By fostering transparency and accountability, it not only enhances compliance but also streamlines inventory management. As the saying goes, “a stitch in time saves nine,” highlighting the importance of addressing potential issues early. Ultimately, this structured approach enables organizations to navigate the complexities of the supply chain with confidence and precision.